Modern Manufacturing

002 / Cut By Beam

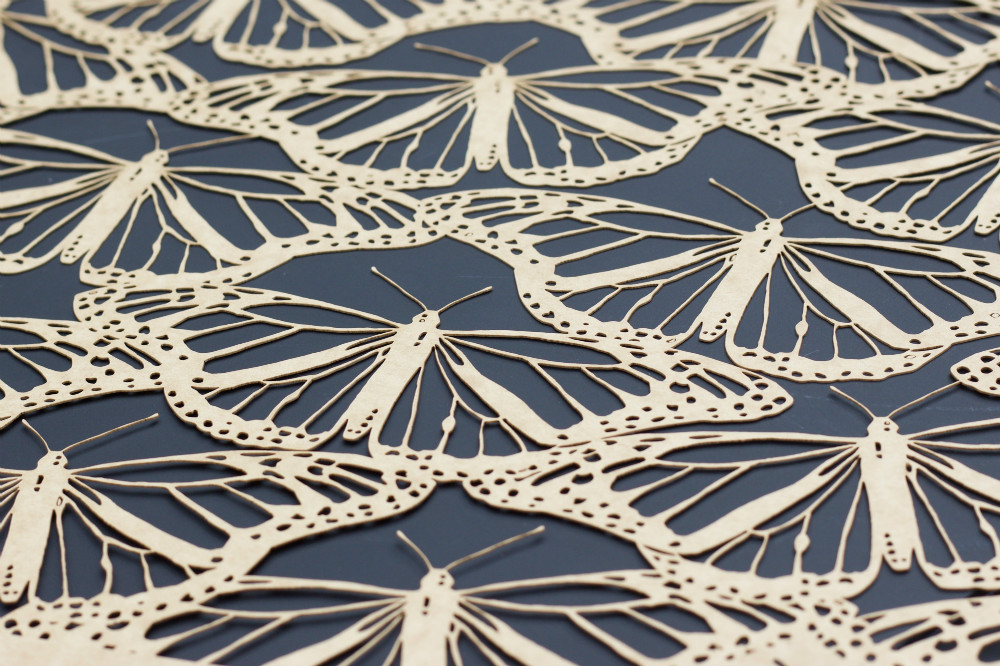

Cut By Beam is a laser cutting and etching service based in Mylor, Cornwall, run by Jenny Shipley.

Like all good workshops, you'll find a resident dog called Purdy.

Photo: Sally Mitchell

Tell us a little about how and why you started Cut By Beam?

I finished at university in a financial crisis where there were very few jobs and not much optimism.

I knew where I wanted to live but the job I wanted there didn’t exist so I figured I was going to have to create it myself. I didn’t know exactly what I wanted to do or how I was going to do it. It was quite a journey of internships, working for other businesses, small and large, doing short courses in all sorts of things and learning as much as I could on the way.

Sometimes the negative experiences are as valuable as the positives because they help you focus on what you don’t want to do as much as what you do want to do.

Did you have any experience of manufacturing / using a laser machine before you started the business?

I had experience with laser cutting from work done during my design degree and always loved the process then. After I left university I also worked for a furniture designer who laser cut laminates to use as decorative surfaces on her work.

I’d never really done any manufacturing as such, I feel that's a roll I fell into. When I first started I thought I would be part making things for other people and part making my own products. In reality I've been so busy doing other peoples work that I don’t have time for my own.

You could class what you do as a manufacturing service. How do you see the service you provide?

It is a funny place to be actually and I do often wonder where I fit in .

A lot of what I do is very much along the lines of a manufacturer, I’d almost say we are more of a 'mini manufacturer'. We are capable of doing very large runs of products but it can be difficult to compete on price in that market. People will sometimes pay more to know we are making their products which is a very special feeling.

I do think we are often suited to smaller batch production. As a business I’d rather focus on quality output rather than having to cut corners and make compromises to squeeze prices down.

Describe a typical day at Cut by Beam HQ?

The workshop is based on a farm so it's usually a walk with the dog first up.

We have 3 laser cutters here so a morning coffee and a run through of what is going on each machine is always a good place to start so we know whats happening.

Day to day there is a lot of variety as the jobs that come in are all different sizes and on different materials. On a typical day we are likely to etch a batch of enamel mugs, make a couple of signs, a few rubber stamps and maybe a set of medals and trophies. Then there are emails and quotes to draw up, invoices to write, files to prep and parcels to send out. It's a busy time.

"As a business I’d rather focus on quality output rather than having to cut corners and make compromises to squeeze prices down."

Do you employ anyone?

I have people that work in here on a self-employed basis. I find it hard to think of myself as a boss, I want the people that work here to feel part of the business and that they are working alongside me rather than for me.

Tell us the best and worst things about being an outsourced manufacturer?

Sometimes the pressure to get it right when you are working on someone elses product is tough. I had some glass table tops to etch a design onto which were extremely large and extremely expensive. We have a lot of processes to ensure everything lines up correctly but that doesn’t stop you from triple checking and feeling pretty nervous about pressing go.

The best bit is probably the positivity and enthusiasim you get back from customers. It is always super rewarding when a new business comes in and you can take their brand or product off the computer screen and make it something real and tangible. I love it.

What is thebest thing you've etched?

Quite recently we etched some leather labels for Hiut Denim. I remember starting out as a business and identifying some dream customers that I would love to be able do work for. Hiut was one of them so there was a great sense of achievement in seeing the business doing exactly what I had always wanted.

What does the term 'modern manufacturing' mean to you?

I suppose in one sense it could be modern in terms of the machinery we are using. Laser cutting is quite a niche and technical area but we are trying to make it more accessible. Really I think it is about being flexible and accommodating to current businesses, makers and their needs.

What do you call your workspace?

It's definitely 'the workshop'. It has been on quite a journey as we have grown and it has undergone a bit of a transformation from a dusty old barn to a pretty awesome little workspace.

Do you welcome visitors?

Yes, but usually by appointment. We are pretty busy and the jobs and machines are all scheduled so its always better to know when someone might pop by. Plus we can make sure we are stocked up on tea and biscuits.

The variety of work that we are able to do here is quite hard to explain so it's often better to see it! Quite often when people come to collect work that we have completed they get super inspired by the work that they see while they are here and didn’t even realise we could do.

How much influence do you take from traditional manufacturing companies? Have you learnt from other laser machinists?

I have a huge interest and respect in traditional craft and like to try and apply that sense of craft in what I do here, although it sometimes feels quite fraudulent when using CNC technologies.

I haven’t really had much contact with other laser machinists. I am quite stubborn and like to work things out for myself. When started out I could only afford quite a basic machine so I had to put a lot of time into trying out different materials and working out all the different speed and power settings that I needed. It worked out quite well and I documented and shared it on social media to begin showing the type of work I was able to create and in turn I picked up customers and people interested in what I was doing.

Where do you think you sit on the spectrum of traditional sub-contract manufacturer to modern creative design agency?

I'd say that it differs from job to job. One person may know exactly what they want, deliver materials and artwork all set up and we just implement their instructions. Other projects can be a much more collaborative process where we can advise and direct where a project might go.

All we need from someone is a basic idea and we can offer a lot of advice about how to get the best results, what materials to use, how to set up artwork or what is and isn’t possible. We also do a lot of artwork in-house so we can deal with the full process if that's what is needed.

What are your working hours?

Officially 9-5 but unofficially quite a bit more than that. I find it quite difficult to switch off from emails especially and am often reading and answering work emails at home. The workshop is such a busy place there are always distractions with machines beeping and phones ringing so its often easy to construct emails at home sitting on the sofa.

Where do you go for advice?

Since having people working here with me I have realised how great it is to have someone else to talk things through with day to day.

I feel like the business has got to a point where I need someone to talk to about some of the changes and developments we are going through so I am looking to get some kind of mentor lined up. It can be difficult working by yourself and easy to feel isolated so talking to other small business and makers is always helpful and usually reassuring as quite often we all have the same worries.

Which other manufacturers inspire you?

I am surrounded by other small scale manufacturers, I guess they make up a lot of my customer base. I find them all pretty inspiring. There is something so positive about people that go out on their own.

What factory would you love to visit and take a look around?

I can’t think of a specific factory. I get to visit quite a few places through work and in general I am fascinated by how things are made, so would be easily entertained.

I love seeing other peoples workspaces and set ups - getting an insight into processes and work flows is really interesting.

What is the best thing about running Cut by Beam?

I love to make things, I always have and this business allows me to do that all day.

It also a privilege to be part of such an inspiring and creative community - we get to work with a huge array of makers, designers and companies most of them doing their own thing, forging their own businesses and careers and just making their own ideas - it's exciting to be a small part of their journeys too.

In addition to providing a service to others, end users can order one-off personalised items. Is this an area you want to grow?

It's an area I have always thought is an important part of the business.

When I started out one of the reasons was that I couldn’t find anyone who would do the small one-off jobs, so it is something that I am keen to always do.

It is a great thing to be able to offer people and amazing how those one-off small jobs can lead on to other things and new connections.

What's next for Cut by Beam?

I’m not sure on that at the moment. The traditional steps are upgrading our machinery, getting bigger premises, a bigger workforce maybe, but there is also something special about where we are at the moment and what we do so I don’t want to lose that.

I quite like the idea of exploring some kind of mobile set up for events or looking at vacant shops on the high street and creating a pop up customising shop.

And finally, any recommendations for who else we should interview?

I am a massive fan of McNair Shirts and they are making some amazing gear. I love their style and tradition and am fascinated by performance wear made of natural materials - plus they are made in the UK.

Find out more about Cut By Beam at www.cutbybeam.co.uk and follow their story on Instagram @cutbybeam.