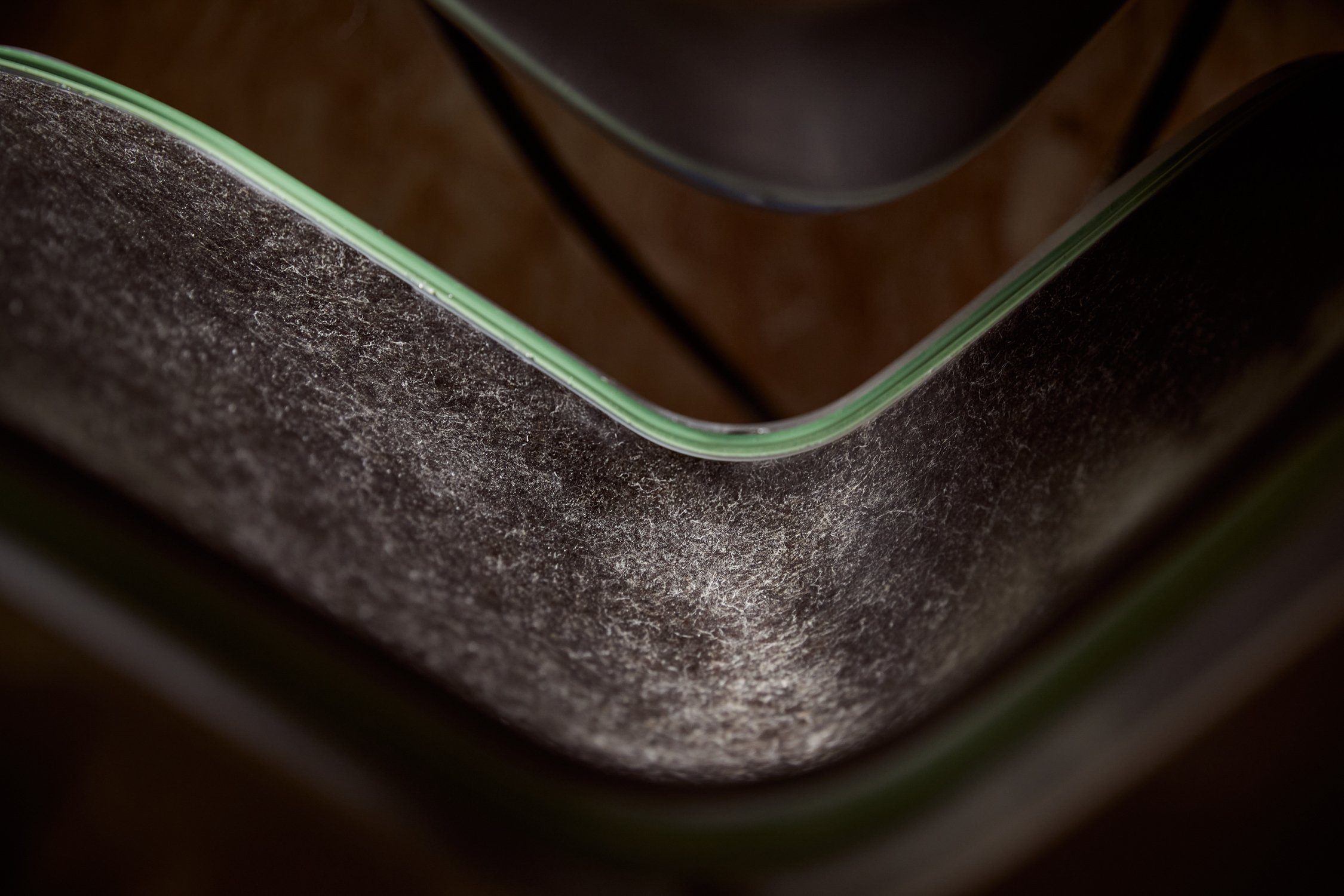

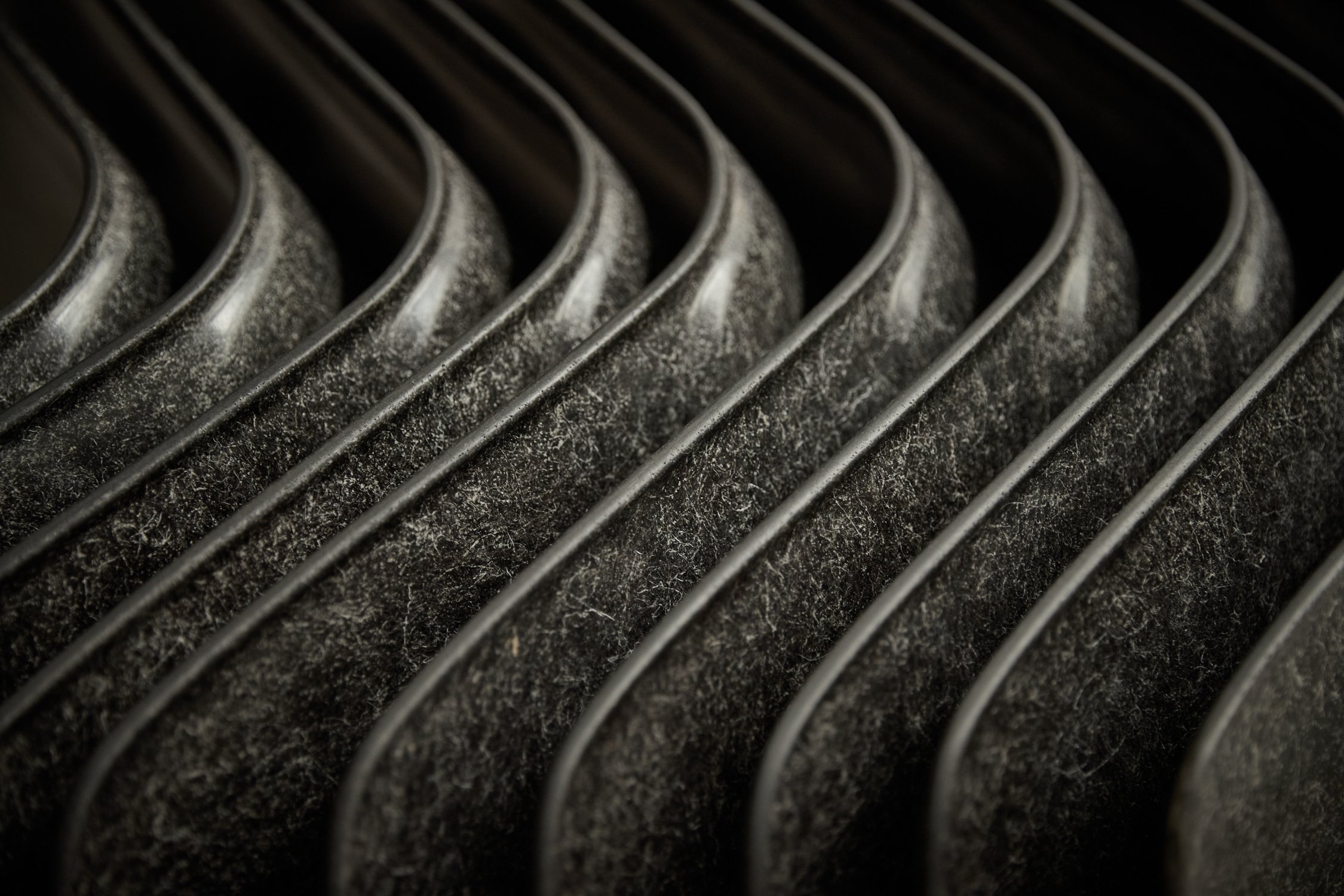

When explaining what goes into Solidwool, it may seem like the process and creation of this incredible composite is fairly simple - wool and bio-resin. However, it has taken years of trials (and errors) and finding just the right balance to make Soldwool what it is today; a complex, unique material that turns the way we work with wool on its head. It is now stronger and lighter, using twice as much wool with half the amount of bio-resin. Better for Solidwool and better for our planet.

Our beginnings came from finding a way to use design for good - and to showcase the remarkable beauty and unique visuality of Solidwool. So when it comes to its creation, we have a dedicated and skilled team who have perfected the art of making this unique material.

Made in Devon, Solidwool is expertly created using a number of complex quantities and precise methods. At every stage of its process our team shares a consciousness and sensitivity towards the value of craft, the appreciation of materials and how these are key in the values and creation of Solidwool.

And with sustainability at the forefront of our mind, we are aware of every element that goes into our design. The wool we use is from the Herdwick sheep, a hardy breed whose fleece is seen as a by-product, but to us is a fleece in which we see beauty and soul - and that tells the story of Solidwool. And it is with our Hembury chair where we see this awareness towards materials and where they come from. Our wooden legs are made using sustainably sourced British Ash hand-turned in Somerset, and the frames are made using recycled steel expertly crafted in Peterborough. Each seat of our Solidwool chair is carefully shaped and hand-finished, with every Hembury assembled by a member of our small team.

The making of Solidwool is a carefully considered process; with each step unrushed and methodical. We are here to master the craft of sustainable design, and that includes a patience and appreciation towards our materials and the environment from which they come. From the beginning of Solidwool, we set out to make design with beauty, conscience and soul - all of which goes into its creation from the people and materials involved in its making.